October is Manufacturing Month

Learning is the key to leveraging opportunities

Discover 6 key things that will help your company leverage opportunities in 2026.

1. ERP and MES Are Not the Same—And You Need Both

- ERP helps manage the business: finance, HR, inventory, purchasing, and customer orders.

- MES helps manage the production: machine performance, shop floor scheduling, quality control, and real-time tracking.

If your ERP says you need to produce 500 units by Friday, your MES tells you which machines are available, what materials are staged, and whether your operators are on schedule. Without MES, your ERP is just guessing.

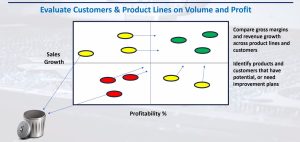

2. AI Is Embedded—Not Optional

AI is no longer a buzzword. It’s baked into modern systems. We saw demos of AI-driven scheduling, predictive maintenance, and even automated quoting. There is opportunity across industries like manufacturing, automotive, real estate, finance, higher education ETC. These aren’t future features, they’re available now but not only in the form of chatbots. Starting by structuring your data to reach your desired outcome and then using Ai tools to consume and interact with the data Ai can boost productivity greatly. If your current system doesn’t support AI, it’s time to start shopping. We talk about some AI tools in our past article.

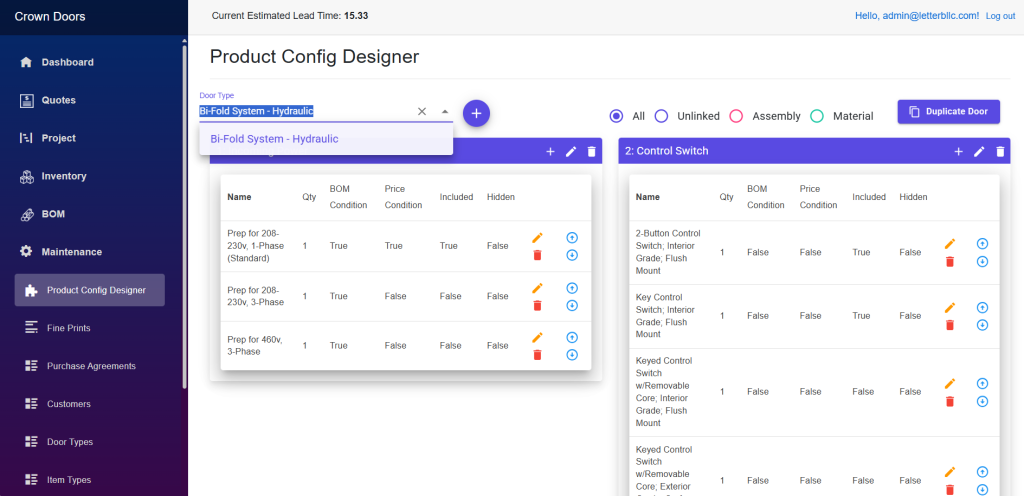

3. CPQ Is the Sales Engine You Didn’t Know You Needed

One Iowa-based manufacturer used CPQ to link their sales team directly to engineering specs. No more back-and-forth emails or manual spreadsheets. The quote was accurate, fast, and ready to go. With direct experience building CPQ systems for manufacturing organizations from the ground up it is clear that quoting is not a standard process and should not be left to off the shelf software. The investment in a custom CPQ tool that feeds the quotes into both the ERP and the MES system will show great ROI for the whole business.

4. Re-Patriotizing Data Is a Real Strategy

A regional supplier moved their MES from the cloud to an on-prem server to meet customer data security requirements. The result? Faster response times and fewer compliance headaches.

5. Lean and AI Can Work Together

One speaker showed how AI flagged a recurring bottleneck in a lean cell—something the team hadn’t noticed manually. The fix improved throughput by 12%.

6. Culture Drives Tech—and There’s Grant Money to Help

At Letter B Global Technologies, we don’t just implement systems, we design them around people. Our cultural design functions ensure that any ERP, MES, or CPQ solution fits the way your team actually works. That means fewer disruptions, faster adoption, and better ROI.

And here’s the kicker:

There’s grant funding available right now for manufacturers investing in Industry 4.0 technologies. Whether you’re exploring AI, automation, or system integration, state and federal programs are offering financial support to help you modernize.

One Iowa manufacturer secured a grant to pilot a smart MES system with on-prem data processing. The funding covered implementation costs and training—accelerating their digital transformation without draining their budget.

Final Thoughts on improving business operations in the future.

If you’re planning a system upgrade a legacy system or a move to a new system, start now. The tools are ready. The insights are clear. And the competition isn’t waiting. Letter B can help with a free consultation to look at your supecific use cases and the types of systems available to help achieve your goals. Just because we develop custom software does not mean that going custom is always the correct route for your needs. Let us help make the fog of the future dicipate and a clear path to success visible.

Transform Your Operations Today

Discover how a custom ERP system can streamline your processes and drive growth. Contact us to explore tailored solutions that meet your unique business needs.